Types of Antenna Coatings

Posted on 19 June 2024

Any time there is RF or any electrical equipment out in the field, it will be subject to a wide range of environmental factors. Extremes of temperature, wind-blown debris, and moisture from rain or snow even dew can all interfere with signals you’re trying to transmit or receive. In many cases, moisture may damage your devices. A variety of protective coatings can mitigate these effects.

Some coatings are painted onto an antenna or other device. Most paints will help improve corrosion resistance and can enhance the appearance of the electronics, often by helping them blend into their surroundings. Also widely used in antenna coatings are infrared reflective paints with a matte finish that protects from infrared radiation and minimizes solar heating. Painted coatings can be effective at preventing oxidation build-up and reducing water damage. However, paints need to be re-applied periodically and can be susceptible to chipping or flaking.

Instead of paint, many RF components use coatings made from various formulations of polymers, or synthetic materials where scientists bind long-chain molecules together to achieve specific properties. This category includes coatings such as epoxy, polyurethane, parylene and benzo-cyclo-butene (BCB).

One of the most ubiquitous polymer coatings in industrial use today is polytetrafluoroethylene (PTFE). PTFE is chemically inert, so even the most caustic agents won’t damage its surface. It is an excellent electrical insulator (electrical conductivity of coatings must be considered for antenna applications), and can withstand very high temperatures, up to 600 degrees Fahrenheit. It has one of the highest breakdown field strengths of all materials (60- MV/m), which can be leveraged for high-power applications. It has a low dielectric constant (2.2) and loss tangent (0.0001) so it does not contribute appreciably to RF loss. With an extremely low coefficient of friction (from 0.04 to 0.10), PTFE is one of the slipperiest substances known. The non-adhesive properties mean that debris, water, and oil won’t stick to the coated surfaces. Even the thinnest coating of PTFE can form an ionic barrier, mitigating the effects of condensate and even salt spray.

Other types of polymers often used as RF coatings are perfluoroalkoxy alkanes (PFA) and fluorinated ethylene propylene (FEP). These materials are also non-reactive and slippery, have a lower melting point but are easier to form into useful coatings.

The protective properties of polymer coatings can be adjusted by adding fillers, such as glass, steel, or graphite. While this may reduce some of the beneficial properties of PTFE, such as chemical resistance, fillers can also make the resulting coating stronger, or add electrical conductivity as required, or tailor the dielectric properties.

While each manufacturer has their procedures, and different molecular makeups will require slightly different approaches, these coatings are generally applied in a multi-step process. The surface is prepared, often by sandblasting or etching the surface.

A prime coat is applied.

The polymer material is sprayed on, often in multiple layers, and then baked to cure into a protective film.

After the protective film has cured, a chemical and abrasion-resistant top coat is applied.

The result is a hard, solid surface that has the properties needed for protective coating.

It is important to note that any coating applied to electronic components may impact the component’s electrical properties. Possible changes in antenna response due to dielectric loading and loss tangent, depending on coating type and thickness applied might be:

Resonant response shifts

Input impedance (VSWR), gain and efficiency degrade

Radiation pattern gain and beamwidth are reduced

When purchasing an antenna, the specifications should be accurate whatever the coating properties might be. For example, Telewave’s Txylan™ coating allows antennas to operate in areas with high concentrations of salt and nitric/sulfuric acids in the air that common powder coats will fail to resist, but with negligible performance degradation compared to unprotected antennas. This is typically why Txylan™-coated antennas are prevalent in industries that operate with corrosive chemicals.

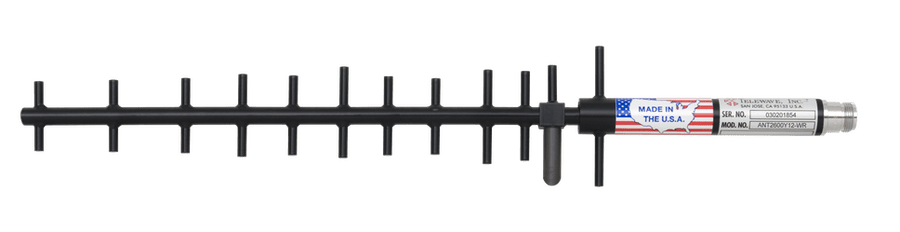

Telewave’s Yagi, Discone, and Dipole antennas all feature the durable, Txylan™ coating that gives them the longevity and reliability that operators need in special weather environments.